Day 2 on the Trail: Buffalo Trace Distillery

Although it’s not officially on the Kentucky Bourbon Trail®, we were probably more excited to visit the Buffalo Trace Distillery than any other. Buffalo Trace has won more awards for their whiskey products than any other distillery in the world. We traveled north to Kentucky’s capital, Frankfort to reach the Trace which is situated on 118 acres bordered by limestone cliffs and conveniently positioned against the Kentucky River. Named for this site which was once a migration path for wild buffalo, a distillery in some form or another has existed here since before 1773. It’s first official name was Old Fire Copper Distillery, and the original distillation permit still reads O.F.C., as this permit has never been reissued. That’s because the distillery has never missed a year of legal whiskey production, even during prohibition. Buffalo Trace was allowed to make whiskey for “medicinal purposes” which required a prescription from a friendly and sympathetic doctor. In those days, everyone was “sick”—even children and babies!

We registered for the Hard Hat Tour several days in advance. This is necessary because the tour does not run as often as others and space is limited. Rather than explain the specific details of whiskey production all over again, I’d like to encourage you to read through the last post if you haven’t already. Although the basic steps are the same, each distillery follows a specific method of production to create their own distinct flavor. I’d like to focus on the details that made the tour at Buffalo Trace unique as well as point out things that we found interesting.

Freddie, our tour guide, is a third-generation employee. He told our group some wonderful stories about the pioneer days of whiskey distillation. In one such story he recounted a time when the first pioneers in the area naturally used the local resources: limestone-filtered spring water and locally-grown grains such as corn, wheat and barley. They found that their product, a clear moonshine they called White Dog, was delicious and smooth. It was, in fact, the best whiskey they had ever tasted. Eager to share their product, they began shipping it down the Mississippi in barrels. When it finally arrived after a long, hot journey, customers complained that the stuff tasted awful. Clearly, something was happening along the way. The barrels were originally used to transport other products such as hog heads or pickles. They quickly learned that used barrels were contaminating their precious White Dog with horrible flavors left in the wood. They immediately started charring the insides of used barrels and using only new oak to transport their product. The resulting whiskey came out brown and rich in flavor from the charred wood. Thus began the use of charred barrels for aging bourbon.

As we walked from the Gallery gift shop to the grain elevators, Freddie pointed out some of the old buildings in the area, including the oldest building in Franklin County, the Riverside house constructed in 1792. The distillery is listed on the National Register of Historic Places under one of it’s former names, The George T. Stagg Distillery. As we stood at the foot of the grain elevator, Freddie explained the process of sampling the arriving grain to test quality and pointed high above us where it is drawn into storage silos. From there, our tour got exciting as we started to climb the steel staircases into the cookhouse.

Within the upper level of the cookhouse sits a giant “measuring cup” used to dose the hammered grains into the cookers. This device rolls back and forth on rails using a hand-crank to position it under each grain elevator and over each cooker. The grains are cooked under pressure for several hours and are mixed at specific temperatures to achieve the necessary effects from each ingredient. Once the mash is properly cooked, it is immediately pumped into fermentation vats. To see them, we crossed the grain delivery area several stories below us through a covered catwalk!

Standing upon the mezzanine that surrounds the huge copper-lined fermenters, we peered into empty vats and saw just how deep and voluminous they are. As we walked among the fermentors we also observed fermenting mash filled almost to the rim where we dipped our hands and tasted the progress. A sign that reads “NO SWIMMING” made light of something very serious. The fermenting mash is so light with carbon dioxide gas that should you happen to fall into the vat, you would fall straight to the bottom. A human body’s high water content would prevent a person from being able to float or to swim to the surface.

As we made our way to the opposite side of the fermentation building we came upon active fermenting mash reaching the end of this stage of production. Floating upon the surface of the mash was a layer of orange oil. Freddie explained that because of the depth of the 92,000 gallon fermentors, these fatty acids float to the surface and can be skimmed from the mash to improve the quality of the whiskey beer. The oil is returned to the processed grain material which is sold as quality livestock feed. The spent grains fetch nearly the same price that was originally paid.

In the next room, sits a one-of-a-kind “micro” distillery among several small-batch fermentors. Tiny by comparison, these vats hold only 2392 gallons and have integrated cooling coils. The modern still which sits entirely within the room is part of Buffalo Trace’s research and experimental department. It is capable of quickly passing the fermented product through hundreds of distillation cycles. We have seen distilleries that perform double and even triple distillation, but this goes way beyond anything done before. Freddie explained that “the best bourbon whiskey is yet to be made.” The idea behind this unique facility is that very small batches can be cooked and then fermented at any temperature, then distilled in a highly controlled manner. This allows the distiller to recreate the environment present in basements and cellars throughout history. Slow, cool fermentation can be used to emulate historical whiskey recipes that have not been able to be reproduced until now. For the first time, families that have owned recipes for generations can distill small batches. The possibilities for ultra-unique and incredibly smooth whiskies represent the future of small batch distillation.

From there, we ducked into another catwalk, criss-crossing the road below until we reached the still house. There are two column stills. One is used to make whiskey, including their flagship product, Buffalo Trace Kentucky Straight Bourbon and the other is used to distill Rain vodka, an organic corn-based vodka distilled seven times. High above the ground, we tasted the clear, raw distillate. By placing the White Dog into your hands, you can sip it to taste the 125-proof as well as the obvious corn flavor. By allowing it to evaporate from your hands, the intense aromas remain. As it dries, you can feel the sticky sugars present in the distillate. Once completely dry, your hands feel soft and smooth. Freddie explained that although most of the fatty acids are removed at the end of fermentation, some of them remain, leaving your skin surprisingly conditioned.

We exited the upper levels of the still house and stood upon a rooftop balcony overlooking the distillery. The valley enjoys a constant breeze which aids in the aging process. From this point, you can see the architectural progression of the warehouses, each constructed using a different technique. Some are flat-roofed brick buildings, insulated and temperature controlled. Others are built according to a different design allowing the full effect of seasonal change. With each warehouse comes the ability to age whiskey barrels differently.

This gives Buffalo Trace the opportunity to choose the specific aging conditions necessary for a desired result. After descending from the mezzanine of the still house, we walked among the aging barrels of Warehouse C, built in 1881 and housing 24,000 barrels. You can smell the sweet aroma of the slowly evaporating “angel’s share” of whiskey. Only the best bourbon becomes Buffalo Trace, and some of this comes from the fourth and fifth levels of Warehouse C. The shuttered windows are opened in the summer and closed during the winter allowing the best temperature swings to affect the aging barrels. The heat draws the whiskey into the resinous wood and the cool months drive it back out again—a process that is repeated as the seasons change. The oak mellows the distillate and imparts the deep amber color and complex flavors that make some of the finest whiskey in the world.

We had a chance to taste and purchase some of the fine products that are produced at the distillery, including the pure White Dog. We also took the opportunity to grab a bottle of their experimental bourbon cream liqueur now available only at the distillery. This may or may not make it to market. Finally, we decided to bring home a bottle of their 20-year Pappy Van Winkle (which we tasted a few days earlier at the Seelbach) and a huge bottle of Rain vodka (we will review this unique product soon). It was fascinating to learn the history of one of the oldest distillation sites in the country and to get a first-hand look at every step of production. If you are ever in the area, don’t pass up the opportunity to visit Buffalo Trace. We highly recommend the Hard Hat tour.

Kentucky Bourbon Trail® is a registered trademark of the Kentucky Distillers’ Association.

From The Shop:

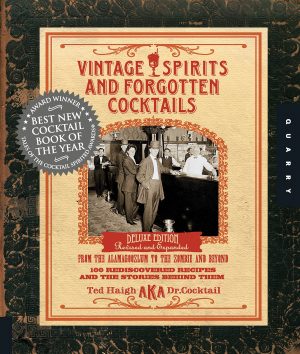

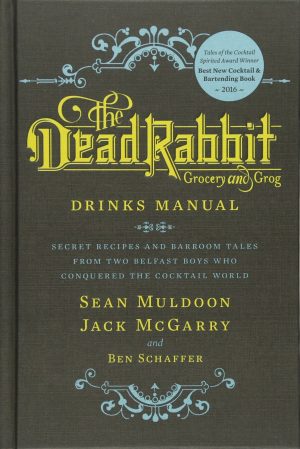

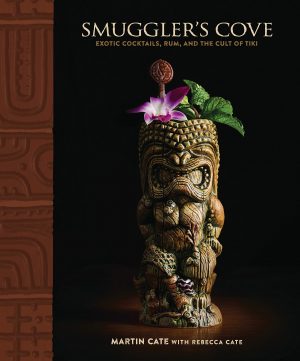

Recommended:

You Might Also Like:

Red Pepper Daisy

Japanese

Chestnut Cup

Sea of Cortez

Jalisco Stroll

Pisco Sour

Stinger

20th Century Cocktail

Atty

Bicycles & Baskets

Briar Patch

Newark

Floridita Cocktail

Iron Cross

Rhubarb Blush

Paper Airplane

Church

Basil Oil Garnish

El Diablo

Singapore Sling

Margarita

Mai Tai

Fangs Out

Vieux Mot

Bitter Branch

Anodyne

Eeyore’s Requiem

Caipirinha

Grounded For Life